About Us

Farm Origins

Boonthida Farm is based in Amphoe Ban Laem, Phetchaburi Province, roughly 130 kilometres away from Bangkok. Phetchaburi (or Mueang Phet)’s – location, like its name (‘Phet’ means ‘gem’ in Thai), is a gem in the rough for a variety of reasons: it has plenty of temples and monasteries, walking trails, pristine beaches with unpolluted waters, and many more! Compared to more popular tourist destinations, and because of Ban Laem’s prime location, the quality of water is much cleaner and free of any chemical pollution due to a lack of industrialisation. Without any toxic waste being deposited into the local waters, aquatic life thrives in the clean environment. With this in mind, we built Boonthida Farm upon 43 rai

(17 acres) of land in the most optimal location for cultivating green caviar seaweeds organically and efficiently. Within a year of establishment, the farm was fully certified by the Fisheries Institute’s Seaweed Division using the organic agricultural method on the 10th of January, 2019. We pride our selves on creating and promoting healthy, high quality green caviar seaweeds products to Thailand’s market.

Our initial means of production involved the usage of repurposed fish cages hanging from a grid formation, allowing the green caviar seaweeds to receive constant sunlight and proper ventilation at the proper depth (30-50 centimeters). This method used 26 rai (10 acres), and we currently employ a total of 60 cages, with 20 batches per cage. This allowed us a daily production rate of 200-400 kilograms of green caviar seaweeds.

After a period of research and experience in the market, we realised that ‘quantity is not the answer’at least for the time being – what was necessary was a consistent means of production that could adapt to the market’s current demand. At present, we only use an eighth of the area originally marked for cage cultivation, which frees us to expand should the need arise.

Ultimately, our fight is not against the market, but against nature itself. Nobody can completely control of the rules of nature, and we are no exception. From our past experiences, we discovered that green caviar seaweeds were not cultivatable year-round. Green Caviar seaweeds primarily grow during the months of January to May, where the arrival of the rainy season in June creates unfavorable salt concentrations in the water. In the past three years, Ban Laem has experienced annual flooding as it is drainage point from the nearby freshwater dam, as well as from the greater city area. This left us with no supply for seven months out of the whole year, which led us to research a means of year-round production and storage of green caviar seaweeds – the green caviar seaweeds Preservation research project. This project was a collaboration with Kasetsart University’s BioTech department and Ratchapat University’s Food Science department, as well as experts from Burapha University and Phra Jomklao Tech, Lat Krabang branch. Our research and experimentation proved a success, and we received certification from the FDA for our new green caviar seaweeds product. From here, we are ready to begin shipments both domestically and internationally.

LOCATION IS EVERYTHING

Amphoe Ban Laem and its surrounding area is suitable for the cultivation of green caviar seaweeds for many reasons, such as:

-A lack of heavy industrialisation

-Good quality of water, free of pollution, and a plentiful environment

-Not a major tourist destination

-Inexpensive property value

-Locals value the protection of the environment during production

ABOUT US

Our farm was created to bring the local community together with agriculture, and we have made efforts to create a local agricultural cooperative. This has yet to happen, but we continue our mission to provide agricultural opportunities to the community. We aim to bolster the production of quality products at fair prices, without any local competition.

Period of Research Involving the Repurposed Fish Cage Method

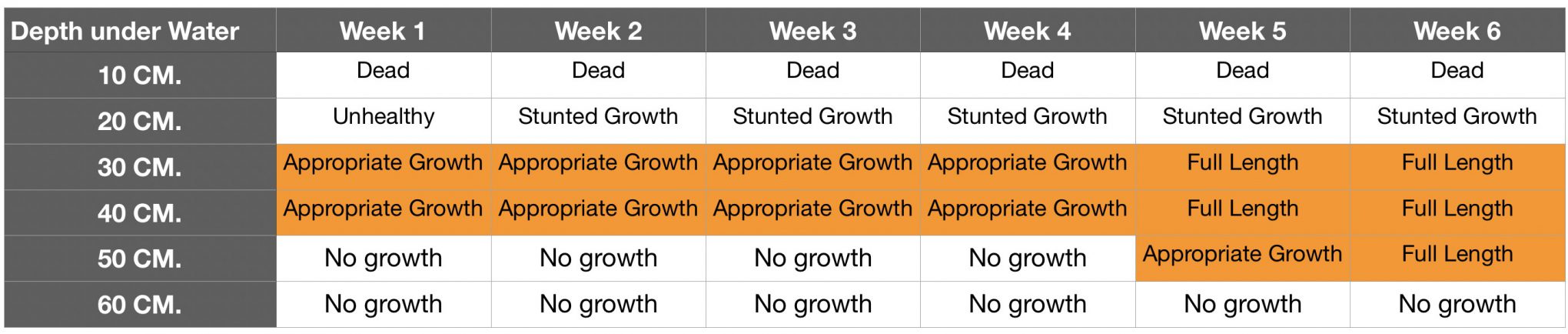

Boonthida Farm first began experimentation of green caviar seaweeds production on 27/12/2016 with a different approach from most farms. The aim was to implement a mixture of positive methods that we will describe below. We used repurposed fish cages hanging from floating grids to cultivate green caviar seaweeds – each batch hangs from empty space within the grid. Our aim was to investigate the ‘appropriate amount of light’ for cultivation, and we attempted to grow green caviar seaweeds beginning at a depth of 10 cm, with each batch being lowered by increments of 10 up until a maximum of 60 cm. The results of this can be found in the table below.

From this, we can conclude that the optimal growth conditions, where the receive the right amount of light in the pond at Boonthida Farm, is 30-50 cm. Anything outside this range fails to grow, or does not meet the expected quality. In certain rainy periods, the green caviar seaweeds may be submerged at depths of up to 60-70 cm in order to preserve the salinity of the water once the water levels normalise. Should the salinity in the water measure at 28-30 ppt after freshwater drainage, we can safely return the green caviar seaweeds back to the original range.

RESULTS OF OUR FIRST EXPERIMENTATION

-We established the optimal depth range for green caviar seaweeds cultivation to be 30-50 cm.

-We also established the optimal growth time before harvest to be 35-45 days.

-We used this information to optimise our production plan by placing 20 batches per cage a day, allowing us to collect it 45 days later at around 200 kilograms a day.

-We produced roughly 60 cages, or 1200 batches of green caviar seaweeds with daily production, allowing us to plan the human labour necessary for collection.

-Once the quality green caviar seaweeds were separated, we found that only 20-30% of the green caviar seaweeds passed the requirements – to look healthy, green and appetising. This means that each cage will only contain 60 kg of quality green caviar seaweeds. At a daily production rate of 400 kg, we can only produce up to 120 kg of the lot.

-With the intention to help nearby farmers revenue, we negotiated purchasing deals with them together, increasing our production capabilities by raising the number of cages used.

STEPS IN GREEN CAVIAR SEAWEED PRODUCTION AT BOONTHIDA FARM

After the 30-45 day growth period, each batch will weigh roughly 10-15 kg. We take each batch for further separation, and we keep roughly 20-30% of each batch.

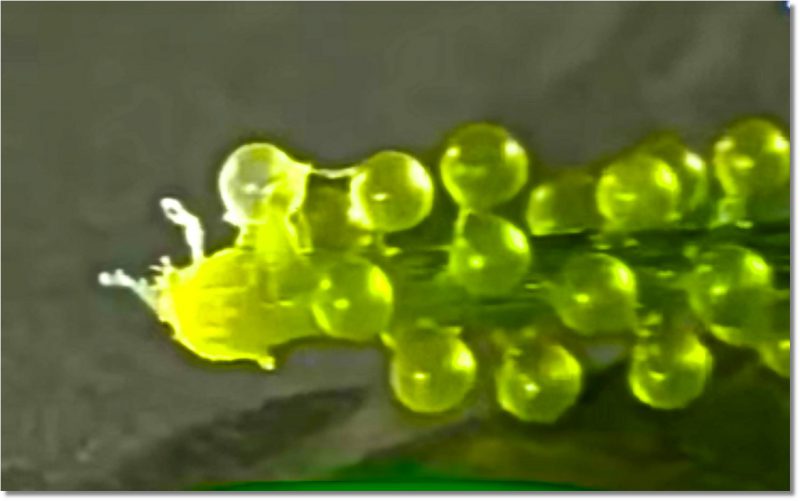

Before separation, we collect the batch and transfer them to sea water tanks with similar salinity range as its original pond for at least 12 hours to allow the green caviar seaweeds to restore their original form.

Once the green caviar seaweeds have rested overnight, then are brought into the separation process, where only the well-formed green caviar seaweeds are kept. Up to 70% or more is thrown away (waste). Each batch takes a considerable amount of labour, as workers at the minimum wage of 300 baht per day can only separate 7-8 kg daily. Premium green caviar seaweeds thus fall to around 40 baht per kg.

After separation, the staff transfer the seaweed back into the filtered sea water pool for another 12 hours, before entering the skimming phase.

Using 35 specialised vats designed for skimming, clean seawater is filtered through the vats. Each vat can be used to clean around 5 kgs. of green caviar seaweeds, using 300 litres of filtered seawater at similar salinity level to the ponds. Compressed air is pumped into the vats which creates small bubbles which collects dust off the green caviar seaweeds and pools them at the top of the vat, which can be cleared hourly. This skimming process takes approximately 12 – 18 hours, before returning the green caviar seaweeds to rest in a pool they need at least of 48 hours for reviving purposes.

Once the green caviar seaweeds have recovered from any damage caused by the separation and skimming process, usually after 48-72 hours, we can then process them in our specialised lab for decontamination and bottling.